Why Choose xProMold

xProMold located in Egypt started at 2014 as a design house. Specialized in designing plastic products and molds for various sectors by owning a practical experience plus advanced tools like CADCAMCAE software, 3D Scanning, and 3D Printing.

To ensure we deliver the optimum solution for our customers, xProMold start mold making in 2017.

xProMold is an integrated solution that provides all services needed to bring your product to life, starting from product design to mass production.

Design

A good start is everything, so we use the most advanced design tools to get the highest

accuracy.

Picking

Mold Making is a continuous chain. so, we pick everything based on a standard to get the best result from the cycle.

Always On Time

We can't say that we are the fastest! but we respect our client's time, so we deliver on

time!

Advice

By discussing our customers need; xProMold provides advice for the best solution, like mold size, best plastic material...etc.

Support

The project doesn't end at delivery !

xProMold

will be your guide whenever you need support.

Our fingerprint

We try to keep our fingerprints on each mold or CNC machining parts we do by using unique and suitable techniques.

All your product need is just under one roof!

Product Design

Turning your idea into a real product started by Product Design, we can say this is almost the success indicator of the product.

xProMold pays attention to this point and helps our client by providing product design services done by qualified team that optimize the design to be ready for manufacturing with the best functional performance.

Product Design

Turning your idea into a real product started by Product Design, we can say this is almost the success indicator of the product.

xProMold pays attention to this point and helps our client by providing product design services done by qualified team that optimize the design to be ready for manufacturing with the best functional performance.

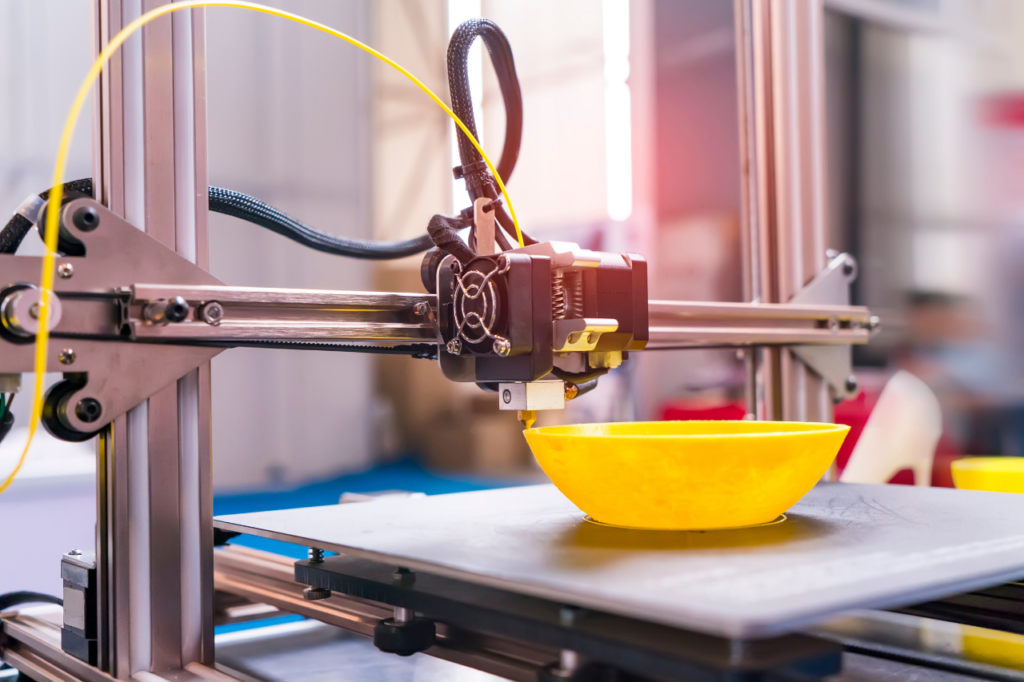

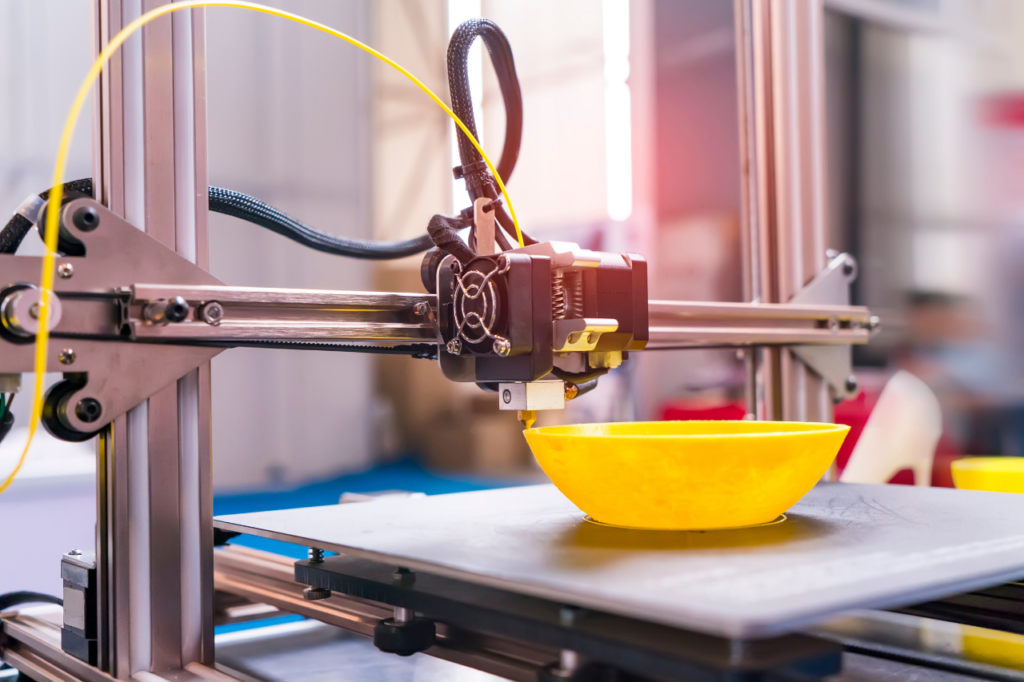

Prototyping

Prototyping is an important step in design because physical feeling is very different from seeing something on the screen. So, xProMold creates initial samples for our clients to check product function, performance, or even shape.

We use 3D Printing or any suitable way to create a functional prototype.

Prototyping

Prototyping is an important step in design because physical feeling is very different from seeing something on the screen. So, xProMold creates initial samples for our clients to check product function, performance, or even shape.

We use 3D Printing or any suitable way to create a functional prototype.

Mold Making

Mold making is the main service xProMoldprovides. in other words, it is the biggest ring in products making chain because some products depend on reverse engineering and that means mold making process still the main step.

xProMold uses the most advanced design software, specified steel, precis machining, and standard components to provide high-quality mold.

Mold Making

Mold making is the main service xProMoldprovides. in other words, it is the biggest ring in products making chain because some products depend on reverse engineering and that means mold making process still the main step.

xProMold uses the most advanced design software, specified steel, precis machining, and standard components to provide high-quality mold.

Plastic Production

To ensure the best quality for our client’s products, xProMold supports production (injection process) for the molds we made. That means you can get your final plastic product (in required quantity) directly from our company without extra effort.

Mold making and plastic production are the endpoints of the same line. Keeping everything done in the same place the result will fit your requirements.

Plastic Production

To ensure the best quality for our client’s products, xProMold supports production (injection process) for the molds we made. That means you can get your final plastic product (in required quantity) directly from our company without extra effort.

Mold making and plastic production are the endpoints of the same line. Keeping everything done in the same place the result will fit your requirements.